How can Manufacturing Process be Improved?

In the dynamic landscape of modern industry, the continuous evolution of manufacturing processes is imperative for businesses to stay competitive.Enhancing manufacturing procedures involves not just boosting efficiency but also elevating product quality, cutting expenses, and mitigating environmental repercussions.. In this article, we will explore various strategies and technologies that can be employed to enhance manufacturing processes.

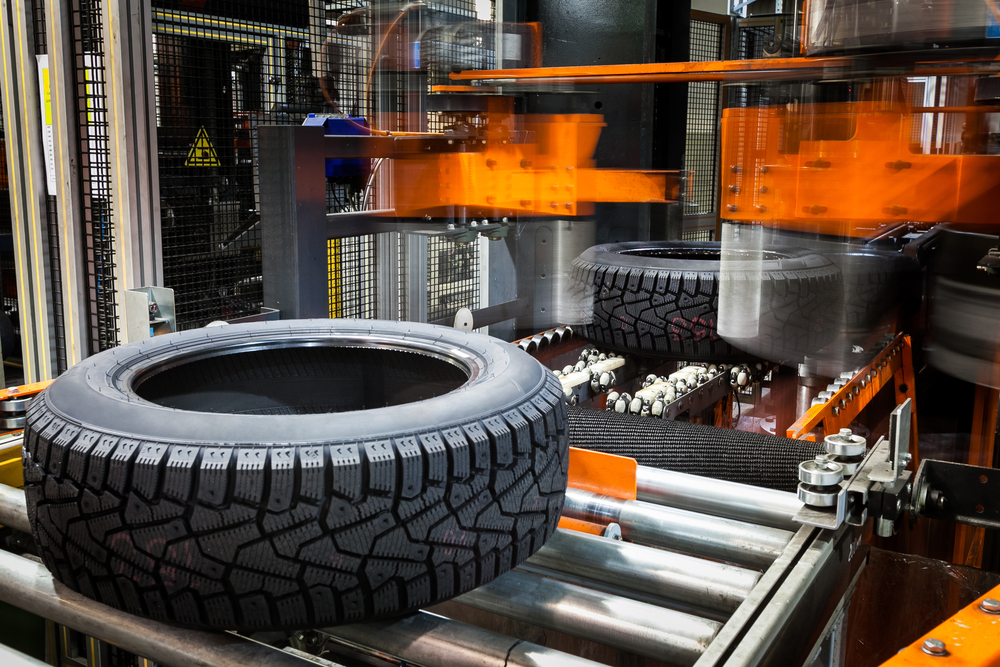

1.Automation and Robotics:

In recent times, the transformation of manufacturing has been propelled by the seamless integration of automation and robotics. Precision and speed characterize the execution of repetitive tasks by automated systems, culminating in heightened efficiency and a diminished margin for human error. The adept handling of intricate assembly processes by robotics has notably elevated both production speed and accuracy.

2.Advancements in Automation and Robotics:

In the realm of manufacturing, the seamless incorporation of automation and robotics has ushered in a transformative era. Precision and swiftness characterize automated systems, enhancing efficiency and minimizing the likelihood of human error. The dexterity of robotics extends to managing complex assembly processes, thereby substantially elevating both the speed and accuracy of production.

3. Data Analytics and Artificial Intelligence:

Harnessing the power of big data and artificial intelligence can optimize manufacturing processes. Predictive analytics can forecast maintenance needs, demand patterns, and potential quality issues. AI-driven systems can continuously learn and adapt, leading to improved decision-making and process optimization.

4. Additive Manufacturing (3D Printing):

Additive manufacturing stands out as an innovative technology, revolutionizing the production of intricate and personalized components. It minimizes material wastage, expedites prototyping, and facilitates the development of detailed designs that were once deemed unattainable. The potential of 3D printing extends to transforming conventional manufacturing approaches.

5. Lean Manufacturing Principles:

Lean manufacturing focuses on minimizing waste and maximizing efficiency. By eliminating non-value-added activities and optimizing workflows, companies can reduce costs and enhance overall productivity. Continuous improvement is a key tenet of lean manufacturing, encouraging a culture of adaptability and efficiency.

6. Supply Chain Optimization:

Efficient manufacturing is closely tied to an optimized supply chain. Advanced planning and scheduling systems can help in better coordinating production with demand. Additionally, embracing sustainable and ethical sourcing practices can contribute to long-term success by ensuring a stable and responsible supply chain.

7. Quality Management Systems:

Establishing effective quality management systems is essential to guarantee that products not only meet but surpass customer expectations. Employing methodologies like Six Sigma and Total Quality Management (TQM) enables the systematic identification and elimination of defects, leading to an enhancement in the overall quality of the manufacturing process.

8. Energy Efficiency and Sustainability:

Manufacturers are progressively acknowledging the significance of sustainability by incorporating energy-efficient technologies, embracing renewable energy sources, and reducing waste. These actions not only contribute to environmental conservation but also yield substantial cost savings in the long run. Sustainable practices are emerging as a pivotal factor that sets companies apart in the manufacturing industry.

9.Employee Training and Engagement:

Skilled and engaged employees are vital for the success of any manufacturing process. Continuous training programs can keep employees updated on the latest technologies and best practices. Fostering a culture of innovation and empowerment can lead to valuable insights and improvements suggested by the workforce.

10. Agile Manufacturing:

In an ever-evolving market, the capacity to swiftly adjust is a noteworthy asset. Agile production incorporates adaptability in manufacturing procedures, enabling prompt modifications to shifts in demand or product requirements. This strategy is especially pertinent in sectors where customization and swift response times are imperative.

Conclusion:

The improvement of manufacturing processes is a multifaceted endeavor that requires a combination of technological innovation, strategic planning, and a commitment to continuous improvement. By embracing automation, leveraging data analytics, and adopting sustainable practices, manufacturers can not only enhance efficiency but also contribute to a more resilient and competitive industry. The future of manufacturing lies in the hands of those who are willing to embrace change and invest in the technologies and practices that will shape the landscape of production for years to come.

READ MORE: WHAT IS BUTTON HEAD SCREWS , AND PROPERTIES , APPLICATIONS

READ MORE: How to start a new startup business on Deepawali 2023