MIG Welding Rods : 6 Types of MIG Welding Rods in 2023-24

In the ever-evolving landscape of welding technology, MIG welding stands out as a versatile and efficient method. One of the critical components in MIG welding is the welding rod, a consumable wire that plays a pivotal role in creating strong and durable welds. As we step into 2023-24, let’s delve into the world of MIG welding rods and explore six distinct types that are making waves in the welding industry.

1. ER70S-6: The All-Purpose Workhorse

The ER70S-6 welding rod stands as the unrivaled cornerstone in MIG welding, celebrated for its adaptability across diverse applications. Esteemed for its exceptional tensile strength and remarkable deposition rates, this rod emerges as the preferred ally for welding carbon and low-alloy steels. From automotive repairs to structural fabrication and general manufacturing, ER70S-6 proves to be the steadfast companion, consistently meeting the demands of skilled welders.

2. ER308L: Stainless Steel Marvel

When the project demands welding stainless steel, the ER308L welding rod takes center stage. With its low carbon content, this rod minimizes the risk of intergranular corrosion, making it perfect for welding austenitic stainless steel types such as 304 and 304L. Industries ranging from food processing to chemical manufacturing benefit from the corrosion resistance imparted by ER308L, ensuring longevity and structural integrity in demanding environments.

READ MORE: WHAT IS BUTTON HEAD SCREWS , AND PROPERTIES , APPLICATIONS

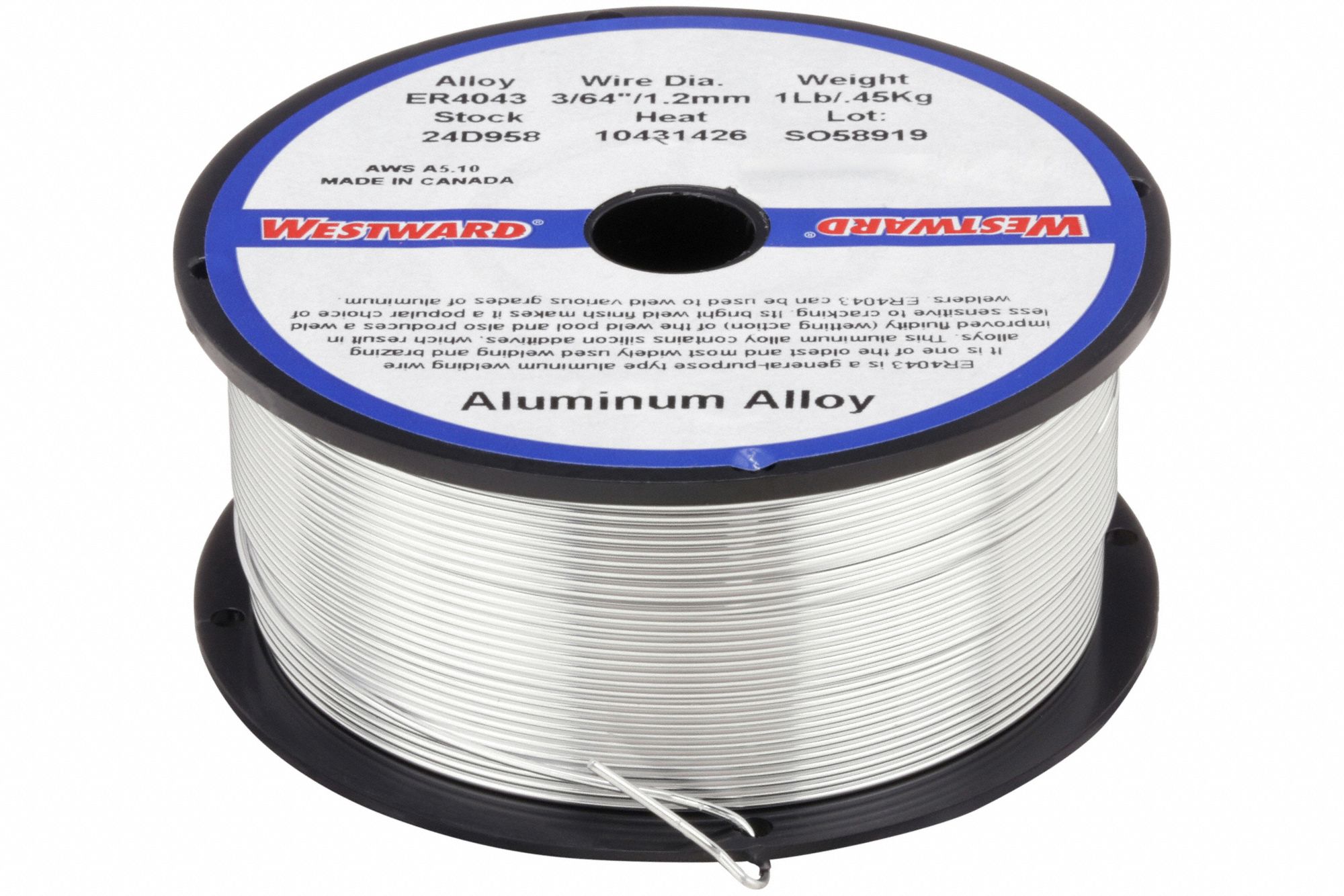

3. ER4043: The Aluminum Specialist

Aluminum welding requires a specialized touch, and the ER4043 welding rod rises to the occasion. Designed for welding alloys with high silicon content, such as 6000-series aluminum, this rod ensures excellent fluidity and crack resistance. Applications in automotive manufacturing, aerospace, and marine industries often call for ER4043 due to its ability to produce aesthetically pleasing welds with minimal post-weld cleanup.

4. ER5356: For Robust Aluminum Welds

When enhanced strength and durability are paramount in aluminum welding, the ER5356 welding rod steps in. Commonly used for welding 5000 and 6000-series aluminum alloys, ER5356 offers superior corrosion resistance and crack tolerance. This makes it a preferred choice for welding components subjected to harsh weather conditions or corrosive environments, such as outdoor structures and marine applications.

/product/92/3593511/2.jpg?2805)

5. ER309L: Tackling the Challenges of Dissimilar Metals

Welding different metals together can be challenging, but the ER309L welding rod specializes in bridging the gap. Ideal for joining dissimilar metals like stainless steel to carbon steel, ER309L ensures a strong and reliable bond. This rod’s low carbon content reduces the risk of carbide precipitation, making it a valuable asset in applications such as pressure vessels, pipelines, and various industrial maintenance projects.

6. ER70S-2: High-Strength Carbon Steel Welds

For projects demanding high tensile strength in carbon steel welds, the ER70S-2 welding rod takes the spotlight. With elevated levels of silicon and manganese, this rod provides exceptional strength and impact resistance. Commonly used in heavy fabrication and structural welding, ER70S-2 excels in scenarios where the welds undergo significant stress, ensuring the longevity and reliability of the welded components.

Conclusion:

As we navigate through 2023-24, the world of MIG welding rods continues to evolve, offering solutions tailored to the diverse needs of the welding industry. Whether you are working with carbon steel, stainless steel, or aluminum, choosing the right welding rod is crucial for achieving strong, durable, and aesthetically pleasing welds. The six types of MIG welding rods discussed—ER70S-6, ER308L, ER4043, ER5356, ER309L, and ER70S-2—stand as testament to the innovation and precision that define the contemporary welding landscape. By understanding the unique properties of each welding rod, welders can make informed decisions, ensuring the success of their projects in the dynamic world of metal fabrication.

READ MORE: How to start a new startup business on Deepawali 2023