What are the 10 types of welding positions?

Welding is a crucial and versatile process in various industries, ranging from construction to aerospace. Understanding the different welding positions is essential for welders to execute their tasks efficiently. Welding positions dictate the orientation of the weld joint, and each has its unique challenges and advantages. In this comprehensive guide, we will delve into 10 types of welding positions, shedding light on their characteristics, applications, and the skills required to master them.

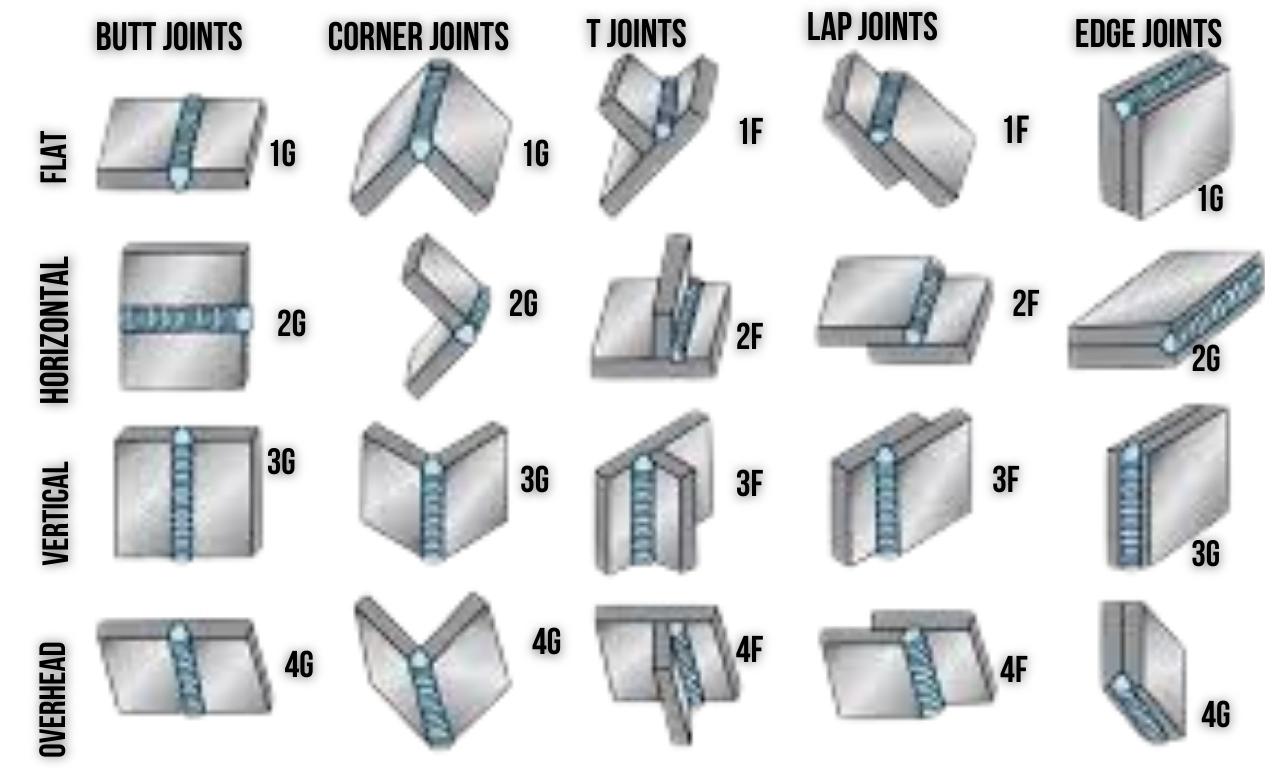

1. Flat Position

The flat position is perhaps the most straightforward welding position, with the weld joint lying horizontally. It is an ideal starting point for beginners as it provides a stable platform for welding. Commonly used in structural welding, the flat position allows for better control over the weld pool, making it easier to create high-quality welds. However, challenges arise when welding thicker materials, requiring greater skill to manage heat distribution.

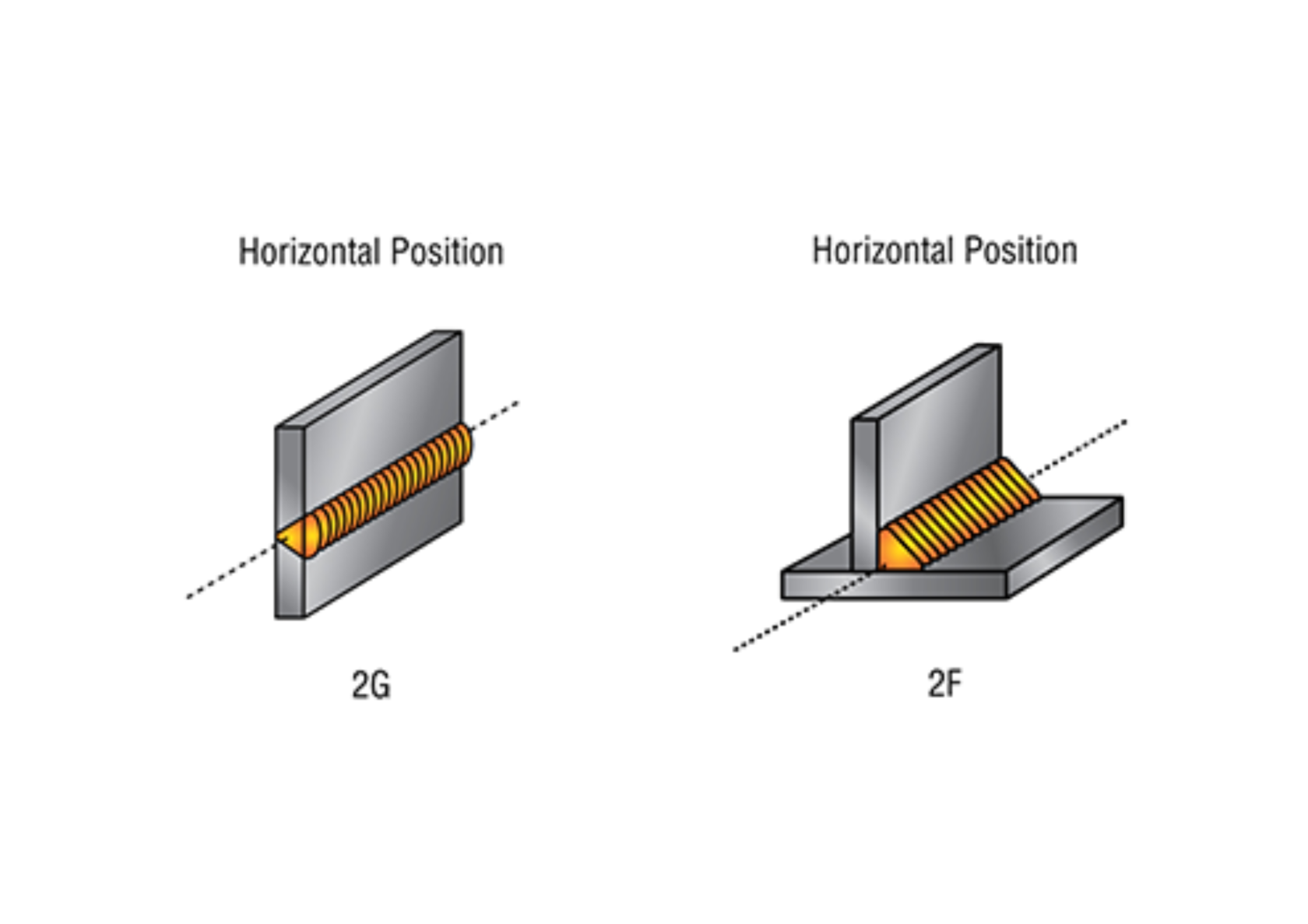

2. Horizontal Position

In the horizontal position, the weld joint is positioned horizontally, but the welding is performed from the side. This position is prevalent in shipbuilding and pipeline welding. Welders must adapt to the gravitational forces affecting the molten metal, ensuring proper penetration and bead formation. Mastering the horizontal position is crucial for professionals working on projects where welding must be executed on the sides of structures.

3. Vertical Position

Welding in the vertical position involves working on a vertical surface, making it a common choice for welders in construction and shipbuilding. Controlling the molten metal becomes more challenging due to the force of gravity, making proper technique and travel speed essential. Vertical welding demands a steady hand and precise control to avoid defects such as undercutting and insufficient fusion.

4. Overhead Position

Considered one of the most challenging welding positions, overhead welding involves welding on the underside of a horizontal surface. This position is common in applications like welding the underside of a bridge or the ceiling of a structure. Welders face difficulties in maintaining the proper weld pool dynamics, as gravity works against them. Skilled technique, a steady hand, and a deep understanding of welding parameters are crucial for success in overhead welding.

5. 1G (Flat Groove) Position

The 1G position involves welding on a flat surface with the weld joint prepared as a groove. This position is commonly found in plate welding and is often used for certifications. Welders must navigate the groove, managing proper penetration and bead placement. It is an essential skill for those working on projects where the weld joint is prepared with a groove for maximum strength.

6. 2G (Horizontal Groove) Position

Similar to the 1G position, the 2G position involves welding on a horizontal surface with a groove in the joint. This position is prevalent in projects like the construction of storage tanks. Welders must adapt to the horizontal orientation and ensure proper fusion and bead appearance. The 2G position requires a combination of horizontal welding skills and groove joint management.

7. 3G (Vertical Groove) Position

In the 3G position, welding is performed on a vertical surface with a groove in the joint. This position is often encountered in projects like the construction of piping systems. Welders must contend with both the vertical orientation and the groove, requiring precise control to achieve the desired penetration and fusion. Mastering the 3G position is vital for welders involved in vertical welding applications.

8. 4G (Overhead Groove) Position

The 4G position involves welding on a horizontal surface with a groove in the joint, making it an overhead welding position. This is a demanding position that requires a high level of skill and experience. Welders must manage the challenges of both overhead welding and groove joint preparation, ensuring the weld’s integrity and strength. Professionals with expertise in the 4G position are highly sought after for projects with overhead welding requirements.

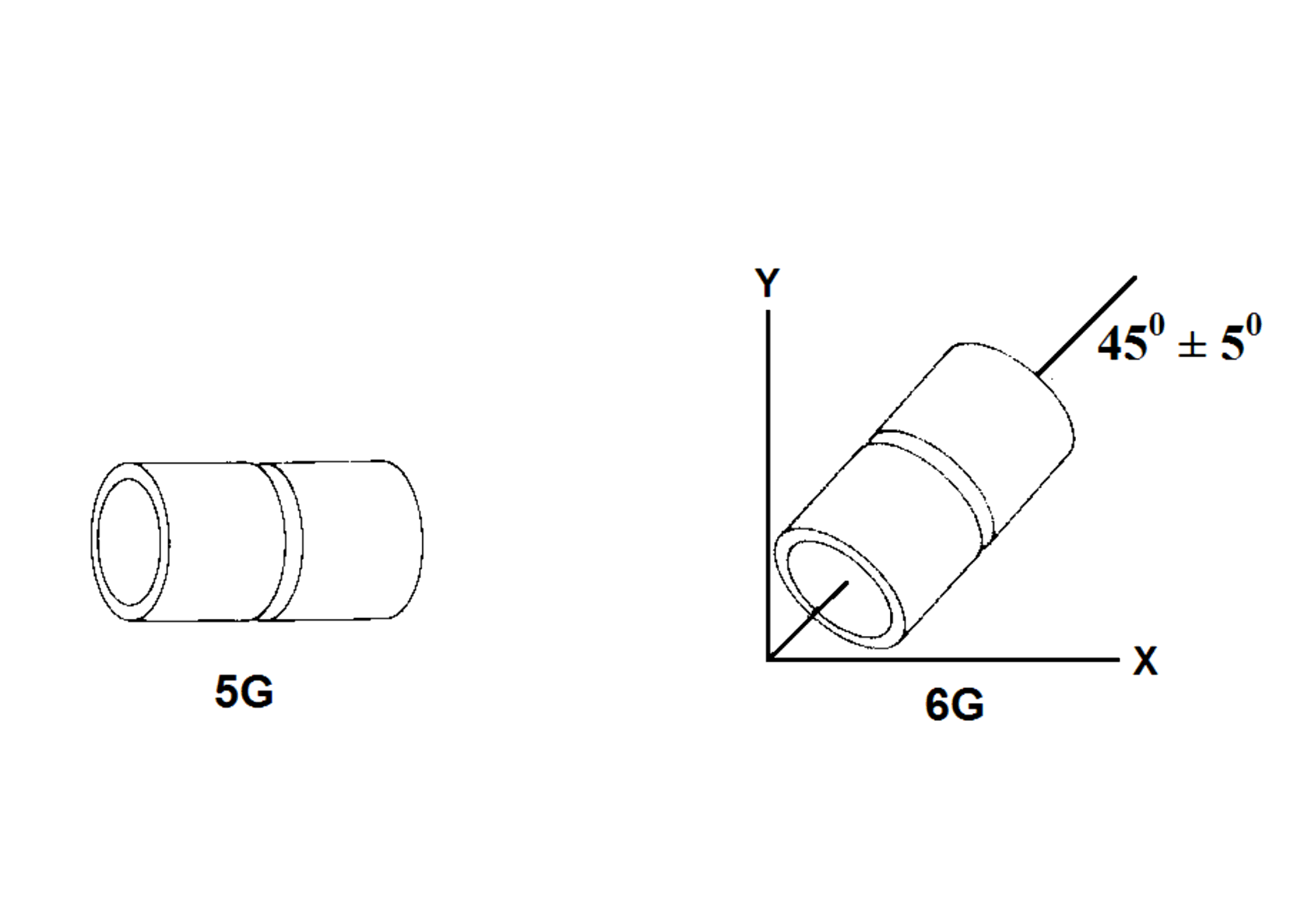

9. 5G (Pipe Welding) Position

Navigating the intricate art of pipe welding in the 5G position demands a welder’s adept finesse, harmonizing with the sinuous contours of the horizontal pipe—a skill vital in sectors like oil and gas, underscoring the indispensability of flawless welds to the intricate tapestry of pipelines shaping industrial landscapes.

10. 6G (Multipositional Pipe Welding) Position

Considered one of the most challenging welding positions, the 6G position requires welding on a pipe at an inclined angle. This position demands a combination of skills from various other positions, including vertical and overhead welding. Welders must possess exceptional technique, adaptability, and a deep understanding of welding principles. The 6G position is a common requirement for welders seeking certification in multipositional pipe welding.

Conclusion

Mastering the diverse world of welding positions is a journey that demands continuous learning and practical experience. Each position presents its unique set of challenges, requiring welders to hone their skills and adapt to different orientations. From the simplicity of the flat position to the complexity of the 6G position, welders play a vital role in shaping the structures and components that form the backbone of various industries. As technology advances, the demand for skilled welders capable of excelling in different positions continues to grow, making expertise in welding positions a valuable asset in the ever-evolving world of metal fabrication.

READ MORE: WHAT IS BUTTON HEAD SCREWS , AND PROPERTIES , APPLICATIONS

READ MORE: How to start a new startup business on Deepawali 2023